Patented technology for fast and safe tipping of vacuum tanker muds and other solid liquid wastes.

Efficiency & Performance

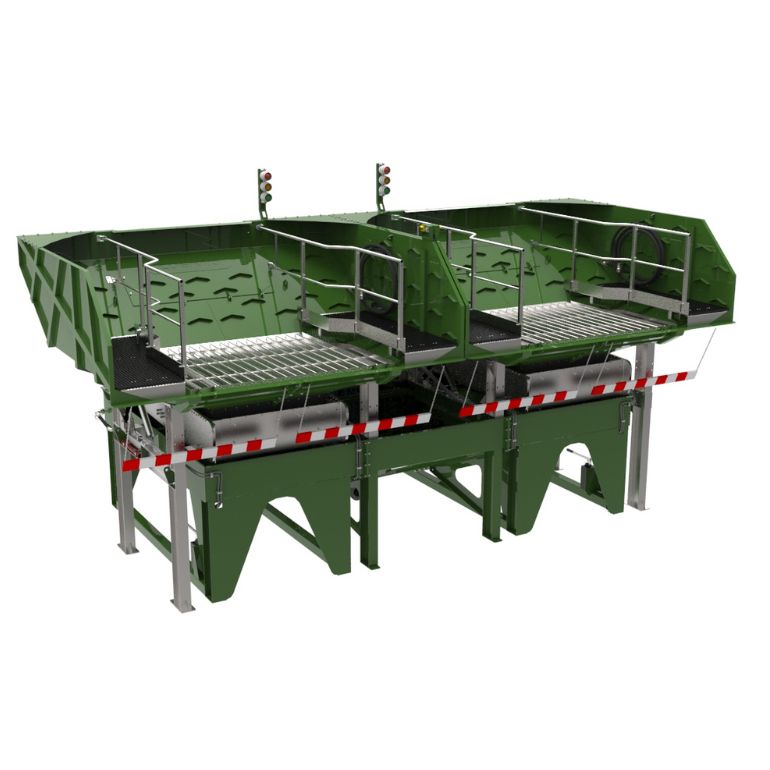

The HYDRO:TIP™ is placed into the ground for direct feed of material from tankers. This direct feed of materials results in quick and easy offloading for maximum efficiency and minimum downtime, allowing tankers to get back on the road faster.

By processing at the fastest rate possible, tanker assets are optimised, and transportation costs minimized. Diverting hydrovac waste from landfill means reduced disposal costs for your business.

Return on Investment

When combined with CDE washing technology, the HYDRO:TIP™ offers maximum dewatering and processing of slurried waste materials to produce clean, reusable sand & aggregates for reuse in the market. Recovered water is cleaned and recycled to use in the washing process and can be further processed to provide jetting water for tankers.

TECHNICAL SPECIFICATIONS FOR THE CDE HYDRO:TIP

| Model | 1RS | GRS | 2RS |

| Weight (kg) | 13,500 | 17,800 | 26,600 |

| Water Requirement (l/s) | Min 17l/s @ 3 barg | Min 22 l/s @ 3 barg | Min 34 l/s @ 3 barg |

| Water Requirement for Hose (l/s) | Min 8 l/s @ 3 barg | Min 8 l/s @ 3 barg | Min 8 l/s @ 3 barg |

| Feed Rate m3/hr* | 30 @ 50% DS | 30 @ 50% DS | 30 @ 50% DS |

| Screening Area (m2) | 7.2 | 7.2 | 14.4 |

| Power Requirement (kW) | 39/32** | 64/57** | 77/63** |

| Dimensions (m) - L x W x H | 5.7 x 4.8 x 5.1 | 5.7 x 6.9 x 6.8 | 5.7 x 9.6 x 5.1 |

* Dependent on material specification. Feed rated based on tankered feed of 3 x 10m3 tankers per hour per screen.

** Total power requirement dependent on HYDRO:TIP pump option.

Patented hydro excavation waste solution: UK - GB 2566260 | Canada - 3065866 | Australia - 2018280016